Metal Cutting Techniques Overview

Along with the increasing demand for metal cutting, new cutting technologies are being developed; which are more precise and more economical. When it comes to metal processing techniques used nowadays; the most common ones are laser cutting, plasma cutting, or water jet cutting. The choice of the cutting technique greatly affects the overall cost of metal positions making, ie structures, and their quality as well. The question is, which is the best metal cutting technique?

The comparison of different metal cutting techniques

Laser metal cutting

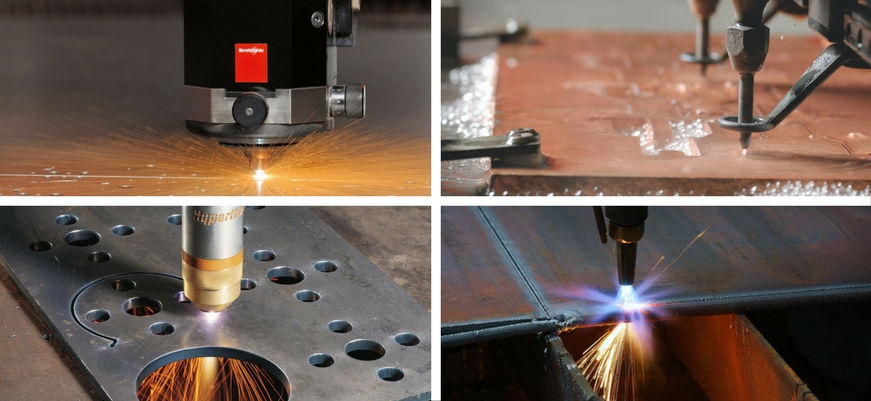

Laser metal cutting has been in use for 25 years, and cutting technology is continually improving. From the initial use of lasers, modern technology, in particular CNC, has enabled increased precision and economical laser cutting, making it one of the most affordable cutting techniques. Depending on the strength, laser technology can cut soft metal up to a 12.7 millimeters of thickness, inox of 10 millimeters maximum thickness and aluminum of 5 millimeters maximum thickness. The maximum metal thickness that can be cut with laser is 25 mm for structural and stainless steel, and 15 mm for aluminum.

Laser metal cutting is most commonly used for cutting homogeneous structure metals, while impurities and admixtures greatly reduce the quality of the cut. In addition to reduced quality, fused metal resulting as an inevitable cutting product can damage the optical lens of the laser. Today, in practice, there is a growing need for cutting very thin materials requiring additional operations during cutting. Because of the low material thickness, it is necessary to drain the heat resulting from the cutting process itself.

Therefore, laser cutting is being used in cutting various metal types and maximum thickness depending on the power of the laser. With economy and quality; the combination of laser and CNC technology enables the performing of the cut and very complex positions.

Laser Cutting Machine by Bystronic

Plasma cutting

Plasma cutting has been in practice since 1960 when it was first used. In the last five years this cutting technique has experienced a revolution. New cutting methods have been developed that have increased precision, metal thickness and cutting quality.

Plasma cutting as such consists of directing negatively charged gas ions almost instantaneously at the speed of sound, into the metal that is being cut. It should be noted that the metal during plasma cutting is positively charged. After the plasma beam penetration into the metal, temperatures up to 28,000 Co are developed. Due to high temperature, there is a corrosion risk, so the auxiliary gas is also applied when cutting. The choice of auxiliary gas in plasma cutting depends largely on the metal being cut. For example, when cutting stainless steel, air, oxygen or argon and hydrogen blend can be used, and when it comes to aluminum cutting only air can be used as an auxiliary gas.

Plasma cutting is commonly used for metals of thickness of 8 up to 31.75 mm. With the advantage of high cutting speed, plasma cutting is also characterized by high temperature development which can damage the material that is being cut.

Water jet metal cutting

Water jet metal cutting is the same in application and practice as the previous two cutting techniques. The principle of water jet cutting operation consists of accelerating the mix of water and abrasive medium to the sound velocity. At such speed, the water penetrates into the metal that is being cut and just like the previous cutting techniques, cuts the metal.

Water jet cutting parameters are mostly equal for all types of metal being cut. One of the main advantages of such metal cutting is high precision and low temperature developing when cutting. These advantages make water cutting the most acceptable technique for metals up to 100 mm thick. Above 100 mm, water cutter loses the precision and exits from precision ranges of about 0.0076 to 0.381 mm.

Which cutting technique should you choose?

When it comes to choosing the best metal cutting technique, it is first necessary to consider the required precision of the cutting and the properties of the material being cut. In addition, it is necessary to include in the calculation the speed or position where the metal being processed is going to be incorporated.

Laser cutting is therefore recommended for metals that require more complex and precise processing with high precision and cutting efficiency. In practice, this would mean that laser cutting is most economical for metal thicknesses up to 10 mm, which do not have high reflexive properties and medium thicknesses as well. Likewise, plasma cutting is most economical for metals up to 10 mm thick. Most often, plasma cutting is used for sheets of larger dimensions and thicker section. Water cutting is recommended for metals up to 460 mm thick, or temperature-sensitive metals.